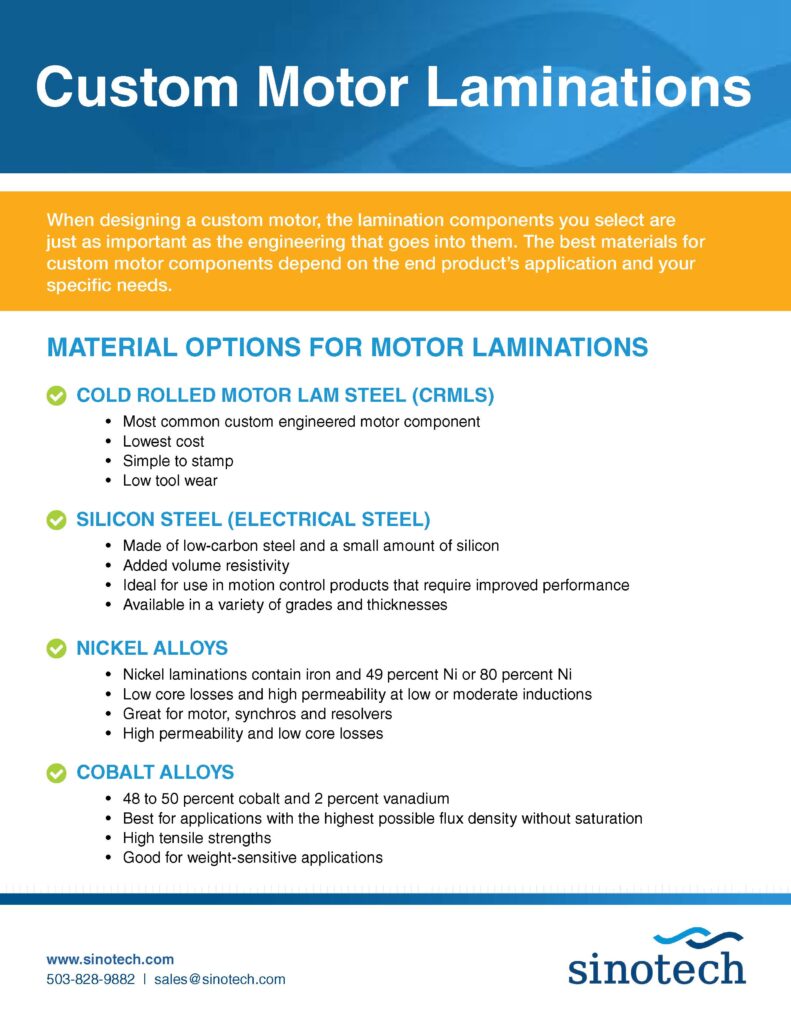

C5 Lamination Coating

A c5 type coating used primarily for preventing sticking of semi processed non oriented electrical steel and cold rolled motor lamination steel during quality anneals.

C5 lamination coating. It also could facilitate welding of rotors stators and minimize welding residue. The coating typically is a phosphate chromate or silicate coating or combination thereof. This is an organic based coating with inorganic fillers added to improve insulation qualities. It also could facilitate welding of rotors stators and minimize welding residue.

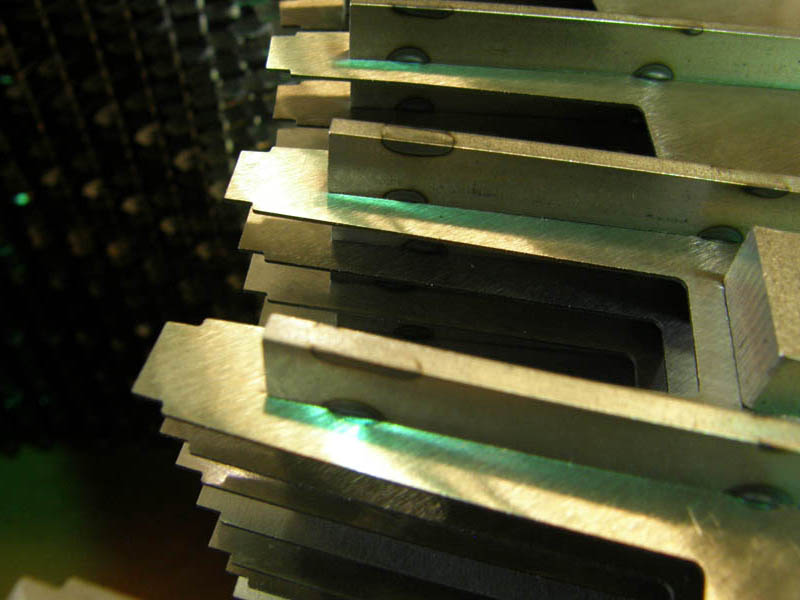

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick. Item a h k j l remark. 50 2000 2000 2000. C5 coating is suggested for use where superior insulation is required after stress relief anneal.

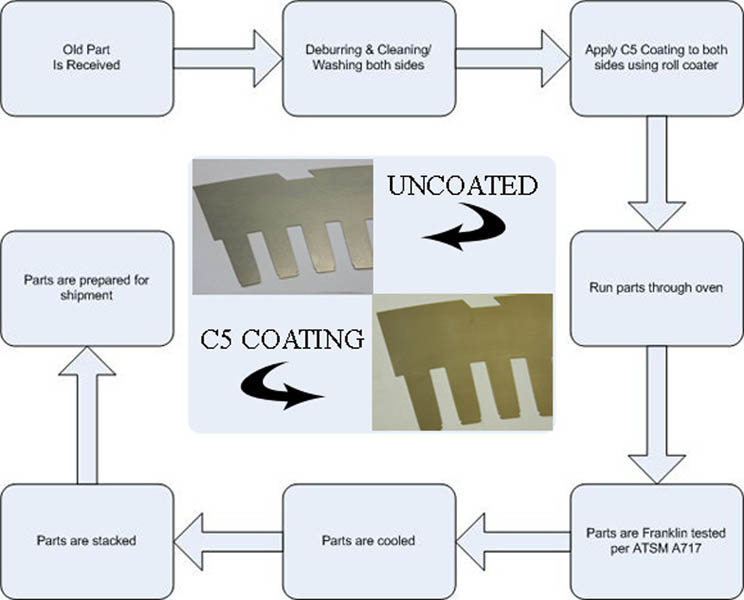

A c5 type coating used primarily for preventing sticking of semi processed non oriented electrical steel and cold rolled motor lamination steel during quality anneals. Franklin testing lamination deburring c5 coating application and oven curing. It is suited for applications in high line speed coating systems. The product is suitable for coating thickness of 1 3 microns.

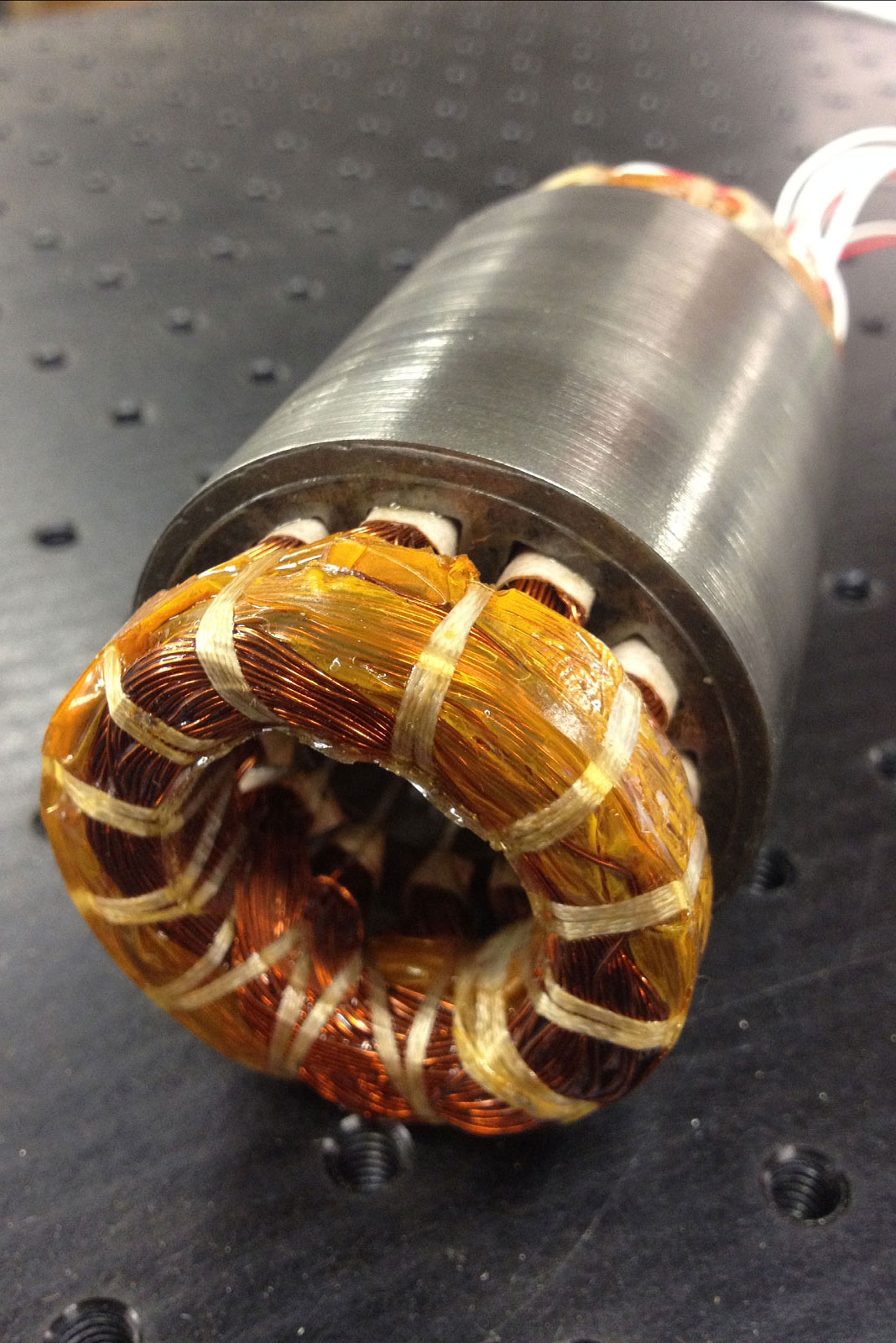

Such coatings are applied to the steel surface and cured by heating. The coatings can be applied to grain oriented electrical steels non oriented electrical steels and cold rolled motor lamination steels. Lamination refurbishment takes an existing part and brings it back into operative condition. C5 coating is used on electrical steels to reduce eddy current heat losses in electric machines.

C6 this is an organic based coating with inorganic fillers added to improve insulation qualities. Here is our c5 coating line from start to finish including. It is well suited for aluminum casting welding and annealing with good adhesion of the annealed layer at coating thickness lower than 2 5 microns. Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

Typical value ampere a per lamination. Typical value ω cm2 per lamination. 1 suralac 7000 is classified as a c 5 coating but can be used as a c 4 coating. All coatings have excellent adhesion and will withstand normal punching.